BREAKING NEWS

National engine projects represent one of the most critical pillars of Turkey’s objective to reduce foreign dependency and achieve strategic independence in defense and industry. Developing engines for land, air, and naval platforms using domestic capabilities is not only a technical achievement but also a significant economic and geopolitical asset. The localization of engines used in defense systems directly enhances export potential while eliminating risks related to supply chain restrictions and external dependencies. Initially focused on performance, reliability, and durability, these projects ultimately aim to establish a high value-added, sustainable, and competitive industrial ecosystem over the long term.

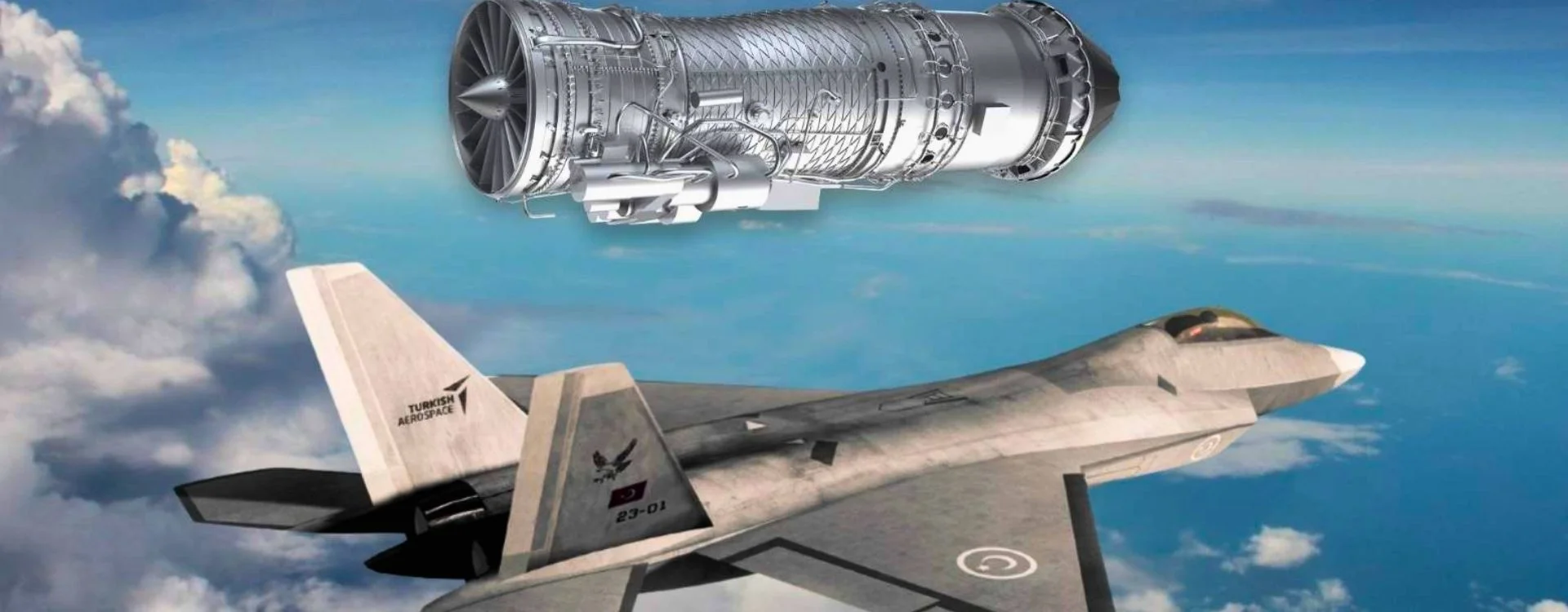

From a technical perspective, national engine projects involve a multi-layered structure that includes advanced materials resistant to high temperatures, cutting-edge manufacturing techniques, extensive testing infrastructures, and intensive research and development processes. Aviation engines, armored vehicle power packs, and diesel or gas turbine engines for naval platforms form the core focus areas of these initiatives. The accumulated know-how gained throughout the lifecycle—from design and prototyping to mass production—creates a strong spillover effect not only in defense but also in civil aviation and automotive industries. As a result, national engine projects stand out as strategic investments that strengthen technological sovereignty, increase export capacity, and provide long-term competitive advantages on a global scale.